Industry Analysis: Automotive 3D Laser Scanners and Their Role in Precision Manufacturing

HANGZHOU , ZHEJIANG, CHINA, December 5, 2025 /EINPresswire.com/ -- As global manufacturing enters a new era defined by digitalization, automation, and precision engineering, the demand for Automotive 3D Laser Scanners continues to surge across advanced industrial markets. From vehicle research and development to quality control, the automotive sector is increasingly relying on metrology-grade scanning technologies that deliver unmatched speed, accuracy, and reliability. Against this backdrop, SCANOLOGY—a world-leading provider of industrial 3D measurement solutions—stands at the forefront of innovation, offering a full portfolio of high-precision 3D scanners designed to accelerate digital transformation across the automotive value chain.

Global Industry Outlook: Precision Metrology Reshaping Automotive Manufacturing

The automotive manufacturing landscape is undergoing notable structural upgrades. Electrification, autonomous driving, lightweight designs, and higher safety standards are encouraging OEMs and suppliers to refine their approach to product development and production. Increasingly complex components, multi-material hybrid structures, stricter tolerance expectations, and shorter prototyping cycles have increased demand for more accurate and efficient measurement tools.

Traditional measurement techniques—such as calipers, gauges, or fixed CMMs—are often insufficient for capturing complex freeform surfaces or large-volume inspection tasks. Automakers are investing in digital metrology, with 3D scanning becoming one of the fastest-expanding solutions. Industry analysis suggests that the industrial 3D scanning market continues to grow at double-digit rates, supported by needs for higher precision, quicker validation, and lifecycle digitalization.

With the wider adoption of Industry 4.0 and digital twin strategies, automotive manufacturers increasingly depend on real-time 3D data for simulation, reverse engineering, assembly verification, and condition monitoring. High-resolution 3D scanning solutions not only improve measurement accuracy but also help reduce rework and production delays. As global competition intensifies, rapidly deployable, non-contact metrology is becoming a key capability.

In this landscape, SCANOLOGY’s integrated hardware-software offerings provide high accuracy, portability, automation compatibility, and adaptable workflows for use throughout vehicle engineering programs.

The Role of 3D Laser Scanning Throughout the Automotive Lifecycle

High-precision 3D scanning now supports a broad range of activities spanning the automotive lifecycle—from concept development to verification. SCANOLOGY’s Automotive 3D Laser Scanners and optical 3D systems contribute to multiple applications, including:

Automotive R&D and Concept Development

During early design phases, 3D scanners enable fast digitization of clay models, prototype parts, and development vehicles. High-resolution scanning assists shape evaluation, aerodynamic studies, and visualization. Portable solutions enable direct conversion of physical prototypes into usable digital files.

Reverse Engineering of Components

Legacy automotive components and benchmarking projects often require reverse engineering. SCANOLOGY scanners provide detailed surface capture for CAD reconstruction and design refinement.

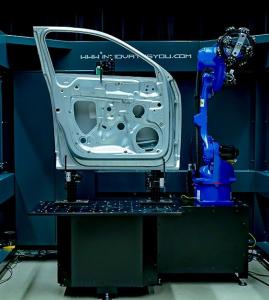

Body-in-White (BIW) Inspection

BIW assembly includes hundreds of welded structures and safety-critical joints. Industrial 3D systems support deviation analysis, alignment checks, and weld evaluation. Automated stations further streamline recurring inspection work.

Quality Control & Inline Inspection

Quality teams apply high-accuracy scanning to compare manufactured parts against digital designs. For stampings, plastics, castings, interior components, chassis elements, and powertrain units, SCANOLOGY systems generate complete geometry in seconds for tolerance assessment and defect analysis.

EV Battery and Powertrain Measurement

Electrified platforms require stringent dimensional control. Scanner-generated 3D data assists uniformity checks and ensures accuracy in EV powertrain components.

Aftermarket, Repair, and Customization

Service, repair, and customization sectors use 3D scanning to analyze damage, support modification, and verify alignment. SCANOLOGY solutions are applied by motorsport teams, automotive designers, and repair facilities.

SCANOLOGY: A Global Participant in Industrial-grade 3D Measurement

Supported by in-house research and system integration capabilities, SCANOLOGY has become a recognized metrology supplier for automotive, aerospace, and industrial users.

Comprehensive Hardware and Software Capabilities

SCANOLOGY develops industrial high-precision 3D scanners and professional scanning tools. Its portfolio includes:

Portable 3D Scanners

Optical 3D Scanners

Automated industrial 3D systems

Color scanning solutions

The company’s work in triangulation, multi-line scanning, and in-process calibration improves operational consistency across environments.

Two Complementary Product Areas

SCANOLOGY focuses on industrial metrology for automotive, aerospace, and heavy machinery. Meanwhile, its sub-brand 3DeVOK offers professional scanning tools for 3D printing, culture and museum usage, medicine, public security, education, and immersive technology development.

Together, the brands address needs from industrial engineering to professional creative applications.

Key Usage Fields

Applications for SCANOLOGY scanners include:

Automotive measurement and inspection

Tooling and mold assessment

Product development and redesign

Measurement of complex freeform shapes

Digital twin environments

Heritage documentation

Medical modeling

Industrial automation workflows

Global Deployment Examples

SCANOLOGY systems have been adopted by:

Automotive manufacturers

Tier suppliers

Aerospace firms

Universities and labs

Integration firms

Design and visualization teams

Users value measurement accuracy, operational efficiency, and workflow adaptability.

Looking Ahead: Industrial Metrology’s Evolving Role

As automotive production transitions toward electrification, automation, and smart manufacturing, the demand for reliable 3D measurement continues to grow. SCANOLOGY maintains its focus on advancing industrial metrology through ongoing development, performance improvement, and international service support. With evolving applications across sectors, SCANOLOGY contributes to progress in inspection, quality evaluation, and engineering analysis.

For additional information, please visit:

https://www.3d-scantech.com/

Global Industry Outlook: Precision Metrology Reshaping Automotive Manufacturing

The automotive manufacturing landscape is undergoing notable structural upgrades. Electrification, autonomous driving, lightweight designs, and higher safety standards are encouraging OEMs and suppliers to refine their approach to product development and production. Increasingly complex components, multi-material hybrid structures, stricter tolerance expectations, and shorter prototyping cycles have increased demand for more accurate and efficient measurement tools.

Traditional measurement techniques—such as calipers, gauges, or fixed CMMs—are often insufficient for capturing complex freeform surfaces or large-volume inspection tasks. Automakers are investing in digital metrology, with 3D scanning becoming one of the fastest-expanding solutions. Industry analysis suggests that the industrial 3D scanning market continues to grow at double-digit rates, supported by needs for higher precision, quicker validation, and lifecycle digitalization.

With the wider adoption of Industry 4.0 and digital twin strategies, automotive manufacturers increasingly depend on real-time 3D data for simulation, reverse engineering, assembly verification, and condition monitoring. High-resolution 3D scanning solutions not only improve measurement accuracy but also help reduce rework and production delays. As global competition intensifies, rapidly deployable, non-contact metrology is becoming a key capability.

In this landscape, SCANOLOGY’s integrated hardware-software offerings provide high accuracy, portability, automation compatibility, and adaptable workflows for use throughout vehicle engineering programs.

The Role of 3D Laser Scanning Throughout the Automotive Lifecycle

High-precision 3D scanning now supports a broad range of activities spanning the automotive lifecycle—from concept development to verification. SCANOLOGY’s Automotive 3D Laser Scanners and optical 3D systems contribute to multiple applications, including:

Automotive R&D and Concept Development

During early design phases, 3D scanners enable fast digitization of clay models, prototype parts, and development vehicles. High-resolution scanning assists shape evaluation, aerodynamic studies, and visualization. Portable solutions enable direct conversion of physical prototypes into usable digital files.

Reverse Engineering of Components

Legacy automotive components and benchmarking projects often require reverse engineering. SCANOLOGY scanners provide detailed surface capture for CAD reconstruction and design refinement.

Body-in-White (BIW) Inspection

BIW assembly includes hundreds of welded structures and safety-critical joints. Industrial 3D systems support deviation analysis, alignment checks, and weld evaluation. Automated stations further streamline recurring inspection work.

Quality Control & Inline Inspection

Quality teams apply high-accuracy scanning to compare manufactured parts against digital designs. For stampings, plastics, castings, interior components, chassis elements, and powertrain units, SCANOLOGY systems generate complete geometry in seconds for tolerance assessment and defect analysis.

EV Battery and Powertrain Measurement

Electrified platforms require stringent dimensional control. Scanner-generated 3D data assists uniformity checks and ensures accuracy in EV powertrain components.

Aftermarket, Repair, and Customization

Service, repair, and customization sectors use 3D scanning to analyze damage, support modification, and verify alignment. SCANOLOGY solutions are applied by motorsport teams, automotive designers, and repair facilities.

SCANOLOGY: A Global Participant in Industrial-grade 3D Measurement

Supported by in-house research and system integration capabilities, SCANOLOGY has become a recognized metrology supplier for automotive, aerospace, and industrial users.

Comprehensive Hardware and Software Capabilities

SCANOLOGY develops industrial high-precision 3D scanners and professional scanning tools. Its portfolio includes:

Portable 3D Scanners

Optical 3D Scanners

Automated industrial 3D systems

Color scanning solutions

The company’s work in triangulation, multi-line scanning, and in-process calibration improves operational consistency across environments.

Two Complementary Product Areas

SCANOLOGY focuses on industrial metrology for automotive, aerospace, and heavy machinery. Meanwhile, its sub-brand 3DeVOK offers professional scanning tools for 3D printing, culture and museum usage, medicine, public security, education, and immersive technology development.

Together, the brands address needs from industrial engineering to professional creative applications.

Key Usage Fields

Applications for SCANOLOGY scanners include:

Automotive measurement and inspection

Tooling and mold assessment

Product development and redesign

Measurement of complex freeform shapes

Digital twin environments

Heritage documentation

Medical modeling

Industrial automation workflows

Global Deployment Examples

SCANOLOGY systems have been adopted by:

Automotive manufacturers

Tier suppliers

Aerospace firms

Universities and labs

Integration firms

Design and visualization teams

Users value measurement accuracy, operational efficiency, and workflow adaptability.

Looking Ahead: Industrial Metrology’s Evolving Role

As automotive production transitions toward electrification, automation, and smart manufacturing, the demand for reliable 3D measurement continues to grow. SCANOLOGY maintains its focus on advancing industrial metrology through ongoing development, performance improvement, and international service support. With evolving applications across sectors, SCANOLOGY contributes to progress in inspection, quality evaluation, and engineering analysis.

For additional information, please visit:

https://www.3d-scantech.com/

SCANOLOGY

SCANOLOGY

+86 136 3412 3772

info@3d-scantech.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.